ΜΗΧΑΝΗΜΑΤΑ

DELTAREG AA 132

SEMIAUTOMATIC STRAPPING MACHINE WITH LATERAL HEAD AND BAYONET

The semi-automatic strapping machines are particularly suitable for solving the problems of packing small pallets.

Equipped with bayonet, hinged and liftable at 90 ° it allows to optimize the spaces when it is not used, 4 pivoting wheels for a fast positioning of the strapping machine, facilitating the passage of the strap through the pallet to be strapped, proposing on the other side the head of the strap.

At this point it is sufficient to insert this in the appropriate opening to activate the strapping cycle. The welding of the strap is carried out by melting it due to a hot blade whose adjustable temperature is kept constant by a thermoregulator.

Electronically adjustable tensioning, pre-launch and throwing of the adjustable strap by potentiometer, button for further strap relaunch.

DELTAREG AA200

AUTOMATIC STRAPPING

Automatic strapping arch machine equipped with steel idler roller working-plate to make the product sliding easy, with automatic strapping operated by a pedal, button or ball on the working-plate.

DELTAREG AA202X

THE MOST PRACTICAL AND UNEXPENSIVE STRAPPING MACHINE ON THE MARKET

Standard semiautomatic strapping machine: simple, robust, low maintenance, available with open or closed frame.

DELTAREG AA500

HIGH SPEED AUTOMATIC STRAPPING

High speed automatic strapping arch machine equipped with inclinable steel working-plate to lay the package, with automatic strapping operated by a pedal, button or photo-eye on the working-plate.

DIBIFLOW 300

THE AUTOMATIC HORIZONTAL FLOWPACK MACHINE SMALL IN SIZE BUT GREAT FOR PERFORMANCE

Dibiflow 300 is the smallest horizontal automatic packaging machine for size but smartest for performance!

Ideal for the food industry, confectionery, ice cream, cosmetic, pharmaceutical… But also ideal for technical items, components, spare parts, various kits, electronic devices, etc…

Designed for all wrapping exigencies in compliance with hygiene and food standards. At the same time, enhancing the image and presentation of the product, with the advantage of marketing and new distribution products.

DIBIFLOW LINE

DIBIFLOW LINE: HIGH TECHNOLOGY – EASY TO USE

Dibiflow Line is the horizontal automatic packaging machines line with high quality features and manufacturing standards. Easy to use, high versatility and fast production change. Wide range of additional accessories. DIBIFLOW LINE is available in different versions depending on the product size.

DIBIPACK 4255 SA EV

DIBIPACK EVOLUTION: THE CUTTING EDGE TECHNOLOGY INHEAT-SHRINKING

Only one operator. Great performances for remarkable outputs. Advanced control and management of cycle.

DIBIPACK 6084 EVX

THE EXTRA-LARGE SHRINK-WRAPPER

In addition to small-size wrapping machines to pack small and medium products, Italdibipack offers also EXTRA-LARGE “one-step®” systems, the Dibipack BIG, the largest models of the Dibipack Evolution line, conceived and designed in order to be the winning answer to the increasing demand of a large-size machine with great capacity and high performances. Ideal to wrap products of large dimensions, with wide surface, such as frames, pictures, panels a.s.o.

DIBIPACK 85130

THE “GIANT” OF SHRINK WRAPPERS

Here is the Dibipack 85130 model, a new-entry in Italdibipack range of EXTRA-LARGE “one-step®” systems, theDibipack BIG, the largest models of the Dibipack line, conceived and designed in order to be the winning answer to the increasing demand of a large-size machine with great capacity and high performances. Ideal to wrap products of large dimensions, with wide surface, such as frames, pictures, panels a.s.o.

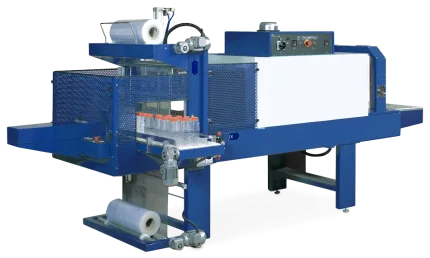

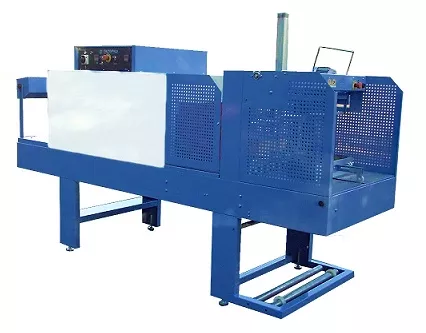

ECOFARD AOL LINE

AUTOMATIC SLEEVE-WRAPPING WITH LATERAL FEEDING

Fully automatic sleeve-wrapper with lateral feeding for “multipackage” (several products wrapped up together on several lines) without an operator.

Practical high-speed sleeve-wrapping machine able to package a wide range of products (bottles, vases, jars, pots, cans, phials, cases etc) and to shelter boxes integrating and/or replacing the use of carton boxes at end-of-line with great management advantages.

The machine is compact and consists in a sealer and a tunnel.

It works in a very simple way: a motorized in-feed belt conveyor, situated at 90 ° from the sealing bar, drives the products from the loading area towards the sealing area. Then a transversal sealing-bar (that has a pneumatic movement and temperature is electronically controlled) cuts and seals the film. At this point the wrapped product enters the tunnel for shrinking.

The models available are 500, 700, 900 and 1250.

Ideal for high outputs.

ECOSPIR A/ID

A COMPLETE SOLUTION FOR PALLET-WRAPPING

High quality-standard, robust and compact machine that may be accessorized with various options according to specific requirements of pallet-wrapping: for example wrapping pallets of large size and remarkable weight, wrapping unstable and not so heavy pallets, etc Ideal for users who has to wrap a high number of pallets.

ECOSPIR FA

IDEAL WHEN THERE ARE LOTS OF PALLETS TO BE WRAPPED

This pallet-wrapper holds all the advantages of the vaious models of the Ecospir line, but in addition it doesn’t need the presence of an operator in loco to work as it is controlled through a remote control by the operator who can do something else in the meantime. The whole pallet-wrapping process, from film clamping up to film cutting at the end of the cycle , is automatic. Ideal to wrap a very high number of pallets.

ECOSPIR LINE

FULLY AUTOMATIC PALLET-WRAPPING LINES

Wide range of fully-automatic pallet-wrapping lines, from the simplest (infeed conveyor – pallet-wrapper – outfeed conveyor) up to the most complete and accessorized ones, both standardarized or customized.

Machines manufactured according to CE rules

ECOSPIR MATIC

HEAVY DUTY TURNTABLE MACHINE WITH AUTOMATIC STRETCH-WRAPPING CYCLE

To further widen the range of pallet-wrapping systems, Italdibipack Group has introduced a NEW pallet-wrapper that functions electrically (compressed air is not required) and is equipped with an exclusive cut and clamp device PAT so that the stretch-wrapping cycle is fully automatic.

ESPERT 11580

SEMIAUTOMATIC SHRINK-WRAPPER FOR EXTRA-LARGE REQUIREMENTS

These systems have been conceived to be used in case more automation is required, in fact the only thing the operator has just to do is to insert the product into the film and to move it onto the sealing area, as the rest of the working cycle ( sealing, product removal and transfer inside the shrink tunnel) happens automatically.

ESPERT 5040 EV

“COMBO” SYSTEM: TO INCREASE YOUR PRODUCCION

These models have been conceived to be used when more automation is required, in fact the only thing the operator has just to do is to insert the product into the film and to move it onto the sealing area, as the rest of the working cycle ( sealing, product removal and transfer inside the shrink tunnel) happens automatically. Ideal for medium-high output productions that need to wrap single and multiple products. Easy changement of size according to product dimensions and shape.

ESPERT 7555 EV

SEMIAUTOMATIC SHRINK-WRAPPER: PERFECT FOR LARGE SIZE PRODUCTS

These models have been conceived to be used when more automation is required, in fact the only thing the operator has just to do is to insert the product into the film and to move it onto the sealing area, as the rest of the working cycle ( sealing, product removal and transfer inside the shrink tunnel) happens automatically. Ideal for medium-high output productions that need to wrap single and multiple products. Easy changement of size according to product dimensions and shape.

JOLLY WORK

THE LATEST INCREDIBLE INNOVATIVE IDEA BY ITALDIBIPACK, THREE SYSTEMS IN ONE

Jolly Work, wrapper and lifter, the 3 in 1 system that solves every packaging need and protects the health of operators. It starts as a simple pallet wrapper with stretch and pre-stretched film (Jolly Wrap), but the addition of the second roll accessory allows the composition of the pallet in half the time (Jolly Twin), while with the addition of the accessory plate (Magic Plate), it also becomes a box lifter and wrapper (Jolly Work), incredibly helpful for the preparation of the load. The device, equipped with various options, can be transformed, without any assembly and disassembly operation, into a pallet wrapper or box wrapper and lifter.

JOLLY WORK TO SAVE TIME, MONEY, EFFORTS AND SAFEGUARD THE HEALTH!

It saves operator effort, preventing back damage, commonly spread among logistics operators, increases productivity and profitability of the work, improves the result, facilitates and allows to wrap higher loads.