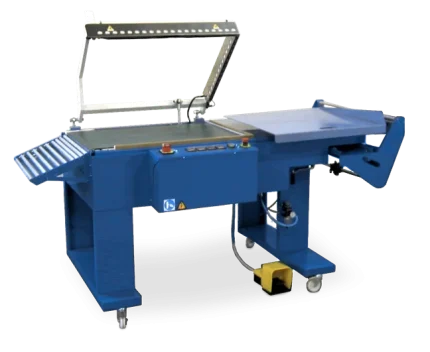

Machine Information:

mecpack five stars std

- Electronic Control Panel with touch sensitivity and intuitive operator interface for setting and controlling all machine functions in the best and simplest way (designed by Italdibipack R&D)

- Ability to memorise multiple work cycles with personalised parameters per cycle

- Film welding bars (transverse and longitudinal) with temperature control by two independent thermostats

- Work cycles and parameter settings are controlled by a microprocessor

- Teflon-coated welding rod

- Automatic package length determination by means of a horizontal or vertical photocell depending on the shape of the product

- Multi-packaging function (packaging of multiple products in series)

- Conveyor belt operation with continuous or synchronized movement with the sealing bar

- Counter

- Central sealing option to save film width

- Motorized film unwinding

- Perforation of the film during film unwinding

- Motorized winding of scrap (film)

mecpack five stars touch

- Machine with electronic control based on Mitsubishi 32 bit PLC controller

- High-speed data transmission software (Mitsubishi's latest generation) which allows absolute accuracy of the specified working parameters (head/tail/welding/times/speed)

- Control of all functions and parameters of the heat shrink oven directly from the L-Sealer touch screen including automatic cooling during shutdown

- Set the speed and control the acceleration and deceleration of the engine directly from the touch screen

- Increase in conveyor belt speed up to 3 mt/1''

- Welding temperature and heat shrink oven temperature control system instead of the ON/OFF method with the PID method for greater accuracy in maintaining the correct temperature

- Touch screen control during manual operation in terms of product feed, film splicing and pulling, and product discharge

- Alarm and failure diagnostics and safety interventions with on-screen reading (over 40 different controls)

- Ability to control the number of pieces produced in descending order, showing both partial and total production

- Ability to store over 100 programs with all relevant working parameters

- Ability to enable/disable film end control and film break control

- Full control of the scraper rewind

- Ability to synchronize with external loading belt

- Continuous loading capability, the loading belt does not stop during welding

- Continuous loading capability, the output belt does not stop during welding

- Ability to perform multi-packing, i.e. measuring the products on arrival before the package is sealed

- Ability to block the welding operation to allow continuous passage of products

- Ability to run a timed envelope. That is, instead of assigning the photocells to read the length of the products, the check is done by the time of arrival of the product (useful function in case of products of odd shape not readable by the photocells).

Manufactured according to the European Regulation

| SPECIFICATIONS – MECKPACK FIVE STARS STD | |

| Power supply | 240/400V – 3PH – N |

| Installed Power | 2,5 kW |

| Overall dimensions (L x W x H) | 2000 x 1000 x 1360(h) mm |

| Sealing bars dimensions | 600 x 500mm |

| Max product height | 180 mm |

| Conveyor belt speed | 22 m / min |

| Productivity | up to 2200 pcs / h |

| Maximum roll width | 600 mm x 250mm |

| Compressed air consumption | 6 Nl / p |

| Compressed air | 6 bar |

| Machine weight | 540 kg |

| Electronic control panel | R&D Italdibipack |

| SPECIFICATIONS – MECKPACK FIVE STARS TOUCH | |

| Power supply | 240/400V – 3PH – N |

| Installed power | 2,5 kW |

| Overall dimensions (L x W x H) | 2000 x 1000 x 1360(h) mm |

| Sealing bars dimensions | 600 x 500mm |

| Max product height | 180 mm |

| Conveyor belt speed | 30 m / min |

| Productivity | up to 2400 pcs / h |

| Maximum roll width | 600 mm x 250mm |

| Infeed conveyor height from the floor | 790 mm (machine on wheels) |

| Compressed air consumption | 6 Nl / p |

| Compressed air | 6 bar |

| Machine weight | 540 kg |

| Electronic control panel | Touch Display (Mitsubishi Software) |

| SPECIFICATIONS – MECKPACK FIVE STARS BIG | |

| Power supply | 240/400V – 3PH – N |

| Installed power | 3 kW |

| Overall dimensions (L x W x H) | 2400 x 1200 x 1360(h) mm |

| Sealing bars dimensions | 800 x 600mm |

| Min product dimensions (W x L) | 100 x 100 mm |

| Max product height | 180 mm (220 mm on request) |

| Conveyor belt speed | 22 m / min |

| Productivity | up to 2200 pcs / h |

| Maximum roll width | 750 mm |

| Roll diameter | 250 mm |

| Min film width | 250 mm |

| Infeed conveyor height from the floor | 790 mm (machine on wheels) |

| Compressed air consumption | 6 Nl / p |

| Compressed air | 6 bar |

| Machine weight | 600 kg |

| Electronic control panel | R&D Italdibipack |

| SPECIFICATIONS – TUNNEL 5525 EV | |

| Power supply | 240/400V – 3PH – N |

| Installed power | 7 kW |

| Overall dimensions (L x W x H) | 1140 x 1000 x 1360 mm |

| Tunnel entrance | 550 x 250 mm |

| Machine weight | 300 kg |